This article was conceived as a typical nuts-and-bolts course, something like: “Everything you wanted to know about all-wheel drive, but didn’t know who to ask”. How the differential drive differs from the one connected with the help of visco-couplers or Haldex-type units, what self-blocking differentials are for… But the more we studied the historical aspect of the issue, the more surprised we were. It turned out that the first passenger car with permanent all-wheel drive was made in Holland a hundred years ago! And in 1935, for example, an all-wheel-drive American racing car almost saved humanity from the Second World War.

Why does a passenger car need all-wheel drive? Now, in the 21st century, this question seems rhetorical. Of course, for the best realization of traction forces of an engine. In order for wheels to idle as little as possible when accelerating on a slippery surface. Four driving wheels are better than two! But humanity has long comprehended this basic truth. Ask any car expert and he will tell you that the era of all-wheel drive on mass passenger cars began only in 1980 with the appearance of the Audi Quattro. He will also name rare predecessors — for example, the 1966 English supercar Jensen FF and the 1972 Subaru Leone 4WD. However, a real expert will immediately make a reservation: first four-wheel-drive Subaru cars didn’t have a permanent all-wheel drive – it was part-time. And this, as they say, is apples and oranges.

Stop-gap solution

A part-time drive on one of the wheel pairs is a palliative solution for passenger cars. The name Part-Time 4WD came from the world of SUVs and cross-country trucks. Such a car, in which one of the axles is constantly leading and the other is rigidly connected if necessary, is able to show its all-wheel-drive characteristics only during off-road overcoming. Solid all-wheel drive has to be turned off when driving on hard pavement. Why? The reason is the so-called power circulation. After all, when turning, front wheels cover a longer distance, moving along arcs of a larger radius, which means that they rotate faster than rear ones. And on cars with this type of drive, the traction on the front wheels decays, and on the rear — on the contrary, increases. In some cases, a tractive torque can be replaced by a braking one, that is, the front wheels will increase the resistance to motion of the car. It’s Ok when there is dirt or snow under the wheels — unless the car becomes worse to steer and moves outwards like a “plow” with the wheels turned out. When moving in a turn, all wheels roll along their trajectories and are forced to rotate at different angular speeds. Therefore, three differentials are necessary for permanent all-wheel drive: two inter-wheel and one inter-axle.

Nevertheless, a blocked all-wheel drive was used on passenger road cars. However, they were more like cross-country cars. For example, in the USSR, back in 1938, the production of small batches of the GAZ-61, the four-wheel drive “Emka” with a six-cylinder engine and a part-time front axle, began. After the war, there was also a production of an “off-road” version of the “Pobeda”, the GAZ-M72, and the Moskvitch-410 with a similar transmission… And the 1972 Subaru Leone 4WD, by the way, was also made to overcome off-road – the clearance of cars with a part-time rear axle was higher than that of conventional front-wheel-drive Subarus.

The Subaru Leone 4WD Station Wagon (1972-1979) is a four-wheel-drive version of the front-wheel-drive car with manually connected rear-wheel drive. The engine has a capacity of 1.4 liters (72 hp) or 1.6 liters (80 hp). In addition to the station wagon, a sedan and a pickup truck were also equipped with all-wheel drive. Until 1989, the rear-wheel drive was connected either manually (on cars with manual transmissions), or automatically — with a multi-disk friction clutch (on cars with an automatic transmission) on all four-wheel-drive Subarus.

So, part-time drive is useless on paved roads where cars spend most of their time — it only makes a car heavier. After all, all this time a car has to “carry” a transfer case with it, in which there is a power take-off to the “temporarily leading” second axis, one more driveshaft, the main gear of the second axle…

Meanwhile, it is very easy to turn part-time all-wheel drive into Full-Time 4WD. It is only necessary to add an inter-axle differential to the transfer case.

Full-time all-wheel drive

Why do we need an inter-axle differential? Two inter-wheel differentials, front and rear, allow each pair of wheels to rotate at different speeds in turns. And the inter-axle one does this work for both driving axles. Therefore, a car with three differentials can easily move with full-time all-wheel drive on any road!

Elementary? Meanwhile, until the early 80s, it was believed that full-time four-wheel drive wasn’t needed for road cars. They said, why should the engine constantly rotate the second pair of wheels and related to them transmission parts on dry asphalt — this is both noise and increased fuel consumption… And only after the appearance of the Audi Quattro, public opinion began to change towards full-time all-wheel drive. After all, the engine thrust is constantly distributed not on two, but on all four wheels, leaving a larger grip margin for the reflection of lateral forces. Such a car turns out to be much more stable in a turn when accelerating or braking with an engine.

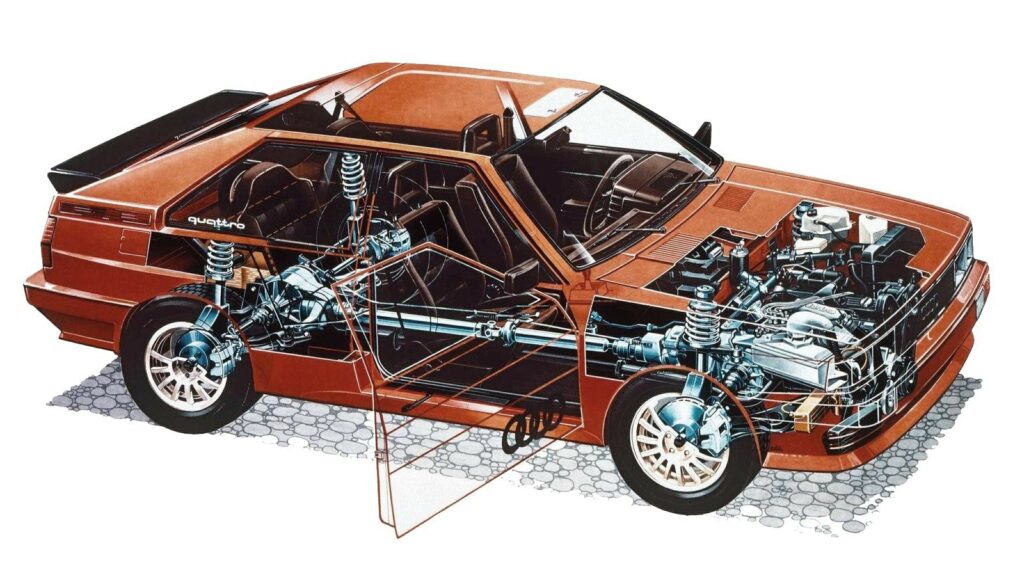

Let’s turn to the drive of the Audi 80 Quattro of the second half of the 1980s. The Quattro scheme is simpler and more compact than the Ferguson transmission. The Torsen self-blocking differential has been used by Audi since 1984. Unlike the differential which is blocked by a visco-coupler, Torsen reacts to changes in the torque implemented by wheels of each of the axles, increases stability during braking and allows to use an ABS, since it is blocked only under traction.

By the way, the Range Rover (1970) and the Russian Niva (1976) are considered to be the first mass-produced cars with inter-axle differentials in the transmission. But since both of these cars still belong to the off-road tribe, the Audi Quattro reaps the laurels of a pioneer among passenger cars.

And what about designers of racing cars – had they not used full-time all-wheel drive earlier? We know that attempts to make four-wheel-drive racing cars were made before the Quattro era. For example, the first post-war project of Ferdinand Porsche was a four-wheel-drive racing car, the Cisitalia 360, with a mid-engine layout and a 12-cylinder 1.5-liter engine. But it is known for certain that the front-wheel drive of this technological wonder was part-time — a racer had to use it only on straight sections of the track, and switch to rear-wheel drive again before turning.

Did the Cisitalia have any predecessors? It turned out, for example, that the same Ferdinand Porsche built an electric car with four driving motor-wheels back in 1900. But a real shock to a car expert will be caused by a 1902 racing car of the Dutch company Spyker. In those “ancient” times, when even brakes were made only on rear wheels, this car had literally full-time all-wheel drive — with an inter-axle differential!

Spyker, a Dutch company for the production of horse-drawn carriages, was founded in 1880 by the Spyker brothers (in Flemish, the surname is spelled Spijker). In 1900, the brothers released the first car of their own design, and two years later, with the help of the Belgian designer Joseph Laviolette, the four-wheel-drive racing Spyker 4WD (1902-1907) was developed with a surprisingly progressive design – with three differentials! There were also three braking mechanisms — two acted on the rear wheels, and another brake was installed on the driveshaft of the front wheels.

So we can safely say that the Full-Time 4WD scheme is more than a hundred years old… Not many four-wheel-drive Spykers were produced — they cost lots of money and could not achieve success in races for various reasons. Other four-wheel-drive racing cars, the Bugatti Tipo 53 and the Miller FWD of the early 30s, were also not much more successful. As for Bugatti, the initiative belonged to the Fiat engineer Antonio Pichetto, who in 1930 proposed to Ettore Bugatti to build a racing car with a 4×4 wheel configuration. And in 1932, three all-wheel-drive Bugatti Tipo 53 were made — with powerful 300-horsepower air-injection engines, with full-time all-wheel drive and with three differentials.

A transmission with three differentials distributed the thrust of a 300-horsepower air-injection eight-cylinder engine to all four wheels. The gearbox, as usual on Bugatti, was installed separately from the engine, the transfer case with the inter-axle differential formed one unit with it. The drive shafts for the front and rear axles were on the left side of the car, a racer sat on the right. Despite the recommendations of the designer of front-wheel-drive cars of that time, Albert Gregoire, not equal angular velocity joints of the Tracta type, but ordinary cardan joints were used in the drive of the front wheels of the Bugatti T53. In addition, they had to use an atypical for Bugatti independent front suspension on a transverse spring in the Tipo 53. All this led to increased loads on the steering wheel — it was extremely difficult to drive the car in turns, although the speeds of gravel turns passing were higher than those of rear-wheel-drive cars of that time. A total of three Bugatti T53 were built, which competed in different races until 1935.

Interestingly, the Italians carefully studied the front-wheel-drive American racing Miller purchased specifically for disassembly before creating the all-wheel-drive Bugatti. In turn, the American Harry Miller became interested in Bugatti’s idea and also decided to build an all-wheel-drive version of his car, having secured the sponsorship of the company FWD (Four Wheel Drive) which produced trucks with a 4×4 wheel configuration. That is how four-wheel-drive racing cars Miller FWD appeared.

American designer Harry Miller became famous in the 20-30s for his racing cars for 500-mile competitions on the Indianapolis Motor Speedway, and his straight eight-cylinder engines with two overhead camshafts were the base of Ettore Bugatti’s engines. Interestingly, Miller built cars with both front- and rear-wheel drive, and in 1932, he made several four-wheel-drive Miller FWD chassis with three differentials in the transmission. One of the four-wheel-drive Millers led the 1934 Indy 500 race, but finished ninth due to technical problems.

It is with these cars that a curious episode is connected: during the race at the Avus track in Berlin in 1935, the four-wheel-drive Miller was driving third when its straight-eight engine couldn’t stand it and literally exploded. At the same time, the pieces of the engine almost reached the stands, in which, among other important people from the National Socialist Party, Hitler himself was sitting! Indeed, it is a rare case when the absence of human victims is worth regretting. If a fragment of a piston had hit the head of one person, the course of world history would have been completely different…

But the Bugatti T53 and the Miller FWD didn’t receive a proper assessment — the “raw” design and constant breakdowns failed. But the next episode in the history of passenger cars with full-time all-wheel drive turned out to be truly fateful.

Ferguson Formula

Let’s return to the theory in order to assess the importance of what was happening in England at the turn of the 50-60s. The inter-axle differential is designed to “untie” both driving axles. For example, the rear wheels are madly skidding, and the front ones are standing still. And the differential doesn’t prevent this in any way!

The cure for this ailment was first invented by designers of SUVs — this is a positive locking. A driver pulls the lever at the right moment, the mechanism tightly fixes the gears of the inter-axle differential – and the transmission turns from the differential, “free”, into a rigidly closed. It was according to this scheme that the first generations of Range Rover, the Russian Niva, and many other SUVs were made. And, by the way, the first Audi Quattro, too — until 1984, a driver had to turn on the blocking of the inter-axle differential in these cars by himself.

Again, this solution is palliative: blocking on a road car can only be activated off-road. You should turn it off on the asphalt. And if a car suddenly gets on a slippery stretch of road, wheels of one axle will start to slip before the others when applying traction.

Is it possible to make the differential block itself automatically when slipping? The introduction of a self-blocking inter-axle differential is associated with the name of the Englishman Tony Rolt, a racer and designer. He and his friend Fred Dixon, also a racer and a true lover of tinkering with car hardware, even before the war opened their own Rolt/Dixon Developments bureau for the preparation of racing cars. After the war, two friends took an interest in the idea of full-time all-wheel drive. Having built an experimental four-wheel-drive “cart” called the “Crab”, in 1950, Rolt and Dixon came under the wing of Harry Ferguson, a successful tractor manufacturer. So the firm Harry Ferguson Research was born.

Ferguson wasn’t interested in racing cars, but he dreamed of a safe road car, the wheels of which wouldn’t slip during acceleration and wouldn’t block when braking. Rolt and Dixon decided to design such a car from scratch – completely, including body, transmission and power unit!

The friends didn’t have enough knowledge, and Claude Hill was invited to the position of a competent chief designer, who left Aston Martin for such an interesting job. But despite Ferguson’s finances, the work was slow — the experimental Ferguson R4 sedan was ready only after six years. But what a car was made: all-wheel drive, with a flat four-cylinders engine, with disk brakes on all wheels and the Dunlop MaxaRet electromechanical anti-lock braking system taken from aviation!

The Ferguson R4 (1956) was an experimental car with the Ferguson Formula transmission. The prototype had a torque converter instead of a gearbox.

But the most interesting thing for us was inside the transfer case of the prototype. Having disassembled it, we would have seen an additional “set” of gears, two ball overrunning clutches and two packs of friction couplings, in addition to the differential. As long as the wheels didn’t slip, the whole thing was quietly idling. But when the wheels of one of the axles began to slip and the difference in the rotational speeds of the output shafts reached a certain value, one of the clutches triggered, squeezed “its” pack of friction couplings — and they braked the differential gears, instantly blocking it and turning the differential drive into a solid one!

The next prototype, the 1962 Ferguson R5, which again took six years to be prepared, turned out to be even more interesting — it was a four-wheel-drive station wagon. Experts of the Autocar magazine, who later tested the Ferguson R5, shared their impressions: “The car reaches the limit of sliding at incredibly high speeds!”

The Ferguson R5 was prepared for mass production in 1962.

But none of automakers has taken up the production of the world’s first all-wheel-drive station wagon with an inter-axle self-blocking differential and ABS – the serial Ferguson would have turned out to be too complicated and expensive. However, in 1962, Rolt still managed to interest the management of the Jensen company — he proposed to adapt an all-wheel-drive transmission for the Jensen CV8 coupe with a 300-hp Chrysler V8 engine, which was then being prepared for mass production. All-wheel drive turned out to be very useful for the powerful and high-speed coupe!

Three years later, the experimental four-wheel-drive Jensen CV8 FF was built. And in 1966, the next model appeared — the Jensen Interceptor, with an even more powerful 325-hp eight-cylinder engine. In addition to the rear-wheel-drive coupe, an option with a modest JFF nameplate was also offered. It was the famous Jensen FF — the world’s first all-wheel-drive production car with a self-blocking inter-axle differential and ABS! The letters FF are Formula Ferguson, the designation of the transmission patented by Rolt and colleagues.

Each automotive journalist of that time mentioned the outstanding stability of four-wheel-drive Jensens and “an almost unlimited thrust margin on wet asphalt”. It’s a pity that Ferguson himself was no longer alive by that time — he died in 1960…

Why are we talking so much about the Ferguson Formula? Because it was Harry Ferguson Research that for the first time in the world paid such serious attention to all-wheel drive as a means of active safety increasing!

We have already said that four-wheel drive leaves a larger grip margin for the reflection of lateral forces. And this is an advantage. But there is also a drawback — the unambiguity of reactions to the fuel supply is lost. If you jam the gas on a powerful rear-wheel-drive car in a slippery turn, this will cause the rear axle to skid. On a front-wheel-drive car, on the contrary, the front wheels will slip, when the traction is applied. Whether it’s good or bad is not the point. The main thing is that the driver always knows how the car will behave in this case.

And which axis will slide on a four-wheel-drive car? This question is not easy to answer. If the front bodywork is currently more unloaded or there is a more slippery surface under the front wheels, the drift will begin. And if the rear wheels have the worst grip conditions, then the car will skid. The reaction can be ambiguous! And it’s not safe.

The Jensen FF (1966-1971) is a four-wheel-drive version of the Jensen Interceptor coupe. The first production all-wheel-drive car with a self-blocking inter-axle differential. The Chrysler V8 engine with a large block having a capacity of 6.3 liters developed 325 hp and drove all wheels through the three-speed TorqueFlite automatic gearbox or a 4-speed manual transmission. On diagonal tires with a dimension of 6.70–15 (like the Volga GAZ-21), the Jensen FF with a curb weight of 1800 kg developed 212 km/h and reached 100 km/h in 7.7 seconds. Other technical features: rack-and-pinion steering gear with power steering, disk brakes of all wheels, the single-channel ABS Dunlop MaxaRet (maximum retardation), independent front suspension on double wishbones and a dependent spring with a Panhard rod at the rear. In 1968, in the UK, the Jensen FF cost 6,000 pounds – about the same as the cheapest Rolls-Royce. A total of 318 four-wheel-drive cars were produced.

Fortunately, Tony Rolt was a racing driver himself, and a very good one — once, in the early 50s, he even won the 24 Hours of Le Mans race. Therefore, Rolt and his colleagues tried to avoid the ambiguity of all-wheel drive from the very beginning by using a nonequalizing inter-axle differential. 63% of the torque was applied to the rear wheels of all cars with Ferguson transmissions, 37% to the front. Thus, the reaction to the increase in traction was close to rear-wheel drive.

The self-blocking differential allowed the Jensen to take the best from both types of transmission. Easy entry into the turn and the absence of power circulation in normal driving modes without slipping are from differential drive. And the best realization of the engine thrust when slipping is from the solid one.

But the overrunning clutches of the blocking mechanism worked rigidly, in a pulsed mode, instantly turning an asymmetric differential drive into a blocked one and vice versa. Therefore, the ambiguity increased when slipping! There was a need for a mechanism that would more flexibly and smoothly change the degree of blocking of the inter-axle differential. And in the late 60s, Tony Rolt with Derek Gardner, who later was the chief designer of Tyrrell race cars, engaged in strange, at first glance, experiments with silicone liquid that was used in drive couplings of radiator fans. Yes, it was Rolt and Gardner who entered the history as the inventors of the visco-coupler!

Self-blocking differentials are developing

A cylinder with packs of friction couplings inside, filled with silicone liquid, was perfectly suited for the purpose intended by Rolt — to brake gears of the inter-axle differential when wheels slip. While the rotation speeds of all wheels are approximately equal, the viskodrive doesn’t interfere in any way with the operation of the inter-axle differential. But now the wheels of one of the axles are slipping. The gears of the inter-axle differential immediately begin to spin, the visco-coupler packs of friction couplings connected with it “whip up” the silicone liquid, and the clutch “seizes”, blocking the inter-axle differential partially or completely.

Such a device blocked the differential smoother and more gently, which had a positive effect on handling. After obtaining patents for a visco-coupler, Tony Rolt formed the FF Developments company in 1971 — specifically to equip cars with four-wheel-drive transmissions of his own design. For example, four-wheel-drive versions of Bedford vans for the British forestry departments, a batch of Ford Zephyr FF cars for the police or Opel Senator 4×4 sedans for the British military mission in Berlin were among the first orders of the company. But the transmission for the American car AMC Eagle, which was produced from 1979 to 1988, was the most important achievement of FFD. It was the ordinary AMC Concord passenger car, but with a 75 mm raised body and enlarged “off-road” tires. And of course, with an all-wheel-drive transmission. Moreover, the production car was for the first time in the world equipped with an inter-axle differential that was blocked by a visco-coupler!

Of course, the AMC Eagle was created mainly for those who periodically storm off-road – all-wheel drive appeared on these cars not because of the desire to achieve more solid acceleration or better stability and handling, as in the case of the Jensen FF supercar or the Audi Quattro. But from the transmission point of view, such driver cars as the Subaru Impreza Turbo or Mitsubishi Lancer Evo from the first to the sixth generation, became the direct heirs of the AMC Eagle. Their inter-axle differentials are also blocked by built-in visco-couplers.

The visco-coupler of the AMC Eagle’s transfer case is a cylindrical body with friction disks, filled with a viscous organosilicon liquid (siloxane), built into the inter-axle differential. When wheels of one of the axles slip, leading and driven packs of disks in the visco-coupler rotate relative to each other, the pressure and temperature inside increase, the viscosity of siloxane changes — and the visco-coupler brakes one of the output gears, preventing it from rotating relative to the body and blocking the inter-axle differential.

The serial coupe Audi Quattro, which appeared in 1981, two years after the debut of the AMC Eagle, was equipped with a conventional open inter-axle differential with positive locking. However, Ferdinand Piech, who was the head of the Audi engineering department in the early 80s, chose a very elegant scheme for the Quattro, which was perfectly suited for the layout of Ingolstadt’s cars. The longitudinally located power unit of the front-wheel-drive car directly pointed to the rear wheels with the end face of the gearbox — it only remained to integrate an inter-axle differential into the transmission box. But Piech’s designers didn’t build a traditional for all-wheel-drive cars scheme with a separate transfer case for the front-wheel drive. The Germans made the secondary shaft of the box hollow — and the drive shaft of the front wheels was passed through it. Truly, the simplicity of genius…

From the very beginning, engineers chose for Audi, unlike FFD, a symmetrical distribution of torque along the axes — 50 : 50. And in 1984, the archaic handles of positive locking of the “center” finally disappeared from cabins of all-wheel-drive Audis — the self-blocking Torsen differential, familiar to us, appeared in the Quattro transmissions. The name Torsen comes from the words “torque sensing” and reflects the ability of this purely mechanical device to instantly and smoothly increase the degree of its blocking in response to changes in torque on the output shafts. Therefore, Torsen doesn’t need a visco-coupler — it blocks itself. Moreover, it is triggered not by the difference in rotation speeds after the start of slipping, but even before it: Torsen is able to respond to changes in grip conditions in the tire contact patch!

By the way, when designers of large SUVs recently began to think about achieving “passenger car” handling, they also remembered about Torsen — it is used in transmissions of such cars as the Range Rover, the VW Touareg/the Porsche Cayenne and the Toyota Land Cruiser Prado.

But let’s go back to the 80s. The triumphant entry of the Audi Quattro on the rally stage was the beginning of an all-wheel-drive boom – all the rally teams of the Group B rushed to create 4×4 versions. One after another, the Peugeot 205 T16, the Metro 6R4, the Lancia Delta S4, the Ford RS200 appeared. All as one — with visco-couplers in self-blocking differentials developed by FFD. Stuart Rolt, Tony’s son, was responsible for working with rally teams at FFD…

In the early 90s, the AZLK plant also turned to FFD when it was decided to design a rally all-wheel-drive modification of the Moskvitch-2141. With the help of the British, a transmission with three self-blocking differentials, front, rear and inter-axle (exactly like on Ford RS200 race cars), was created. The steerability of the experimental four-wheel-drive Moskvitchs in extreme modes deserved the most flattering assessments — the behavior of the cars in sliding was predictable and convenient for racers. It turned out that it is possible to adjust the handling of the car in a wide range by selecting the “rigidity” of blocking visco-couplers in all three differentials. For example, a more “strict” blocking of the rear inter-wheel differential increases a car’s tendency to skid the rear axle. An increase in the blocking coefficient of the front or inter-axle differential, on the contrary, increases the stability margin — a car is less willing to drive into a turn due to slipping and understeer of front wheels.

However, this adjustment is relevant only in one case — with a rally style of driving with slides. Therefore, three self-blocking differentials are the prerogative of the WRC group rally cars. Moreover, as a rule, not visco-couplers are built into the differentials on these cars, but packs of multi-disk clutches with hydraulic drive and with electronic control. In this way, designers get the widest opportunities to configure steerability in real time. For example, the on-board computer can “dissolve” the clutches in all three differentials when entering a turn, turning them into open ones – so that the car can more easily go into a turn. And when the driver starts to accelerate when entering the straight line, the electronics will give the command, and the servodrive will “clamp” the clutches in the differentials in such a way as to achieve minimal slipping of all wheels and, at the same time, not to cross the line of acceptable understeer, beyond which the car will drift off the turn.

By the way, the first controlled clutches were used in Daimler-Benz — in the transmission of the 1986 Mercedes-Benz E-Class 4Matic with the W124 body. Moreover, there were three clutches – if necessary, the electronics first connected the drive to the front wheels, and then sequentially activated blocking of the inter-axle and rear wheel differentials. But such a transmission turned out to be unreasonably complicated. In addition, the electronics alternately connected and disconnected the front wheels on an unstable surface…

The company Porsche was another pioneer of the use of electronically controlled clutches in high-speed cars — there were two clutches on the 1986 Porsche 959, and the electronics worked in four modes that a driver could choose. Later, the Japanese began to manufacture production cars with transmissions of similar complexity — this is, for example, the Mitsubishi Lancer Evo, the most advanced all-wheel-drive road car of all that have ever been tested by the popular Russian magazine Autoreview. The evolution with the inter-axle controlled ACD (Active Central Differential) and the rear AYC (Active Yaw Control) differential with active torque distribution is able to work wonders…

Instead of a differential

While rally engineers put their mind to self-blocking mechanisms, designers of mass passenger cars, on the contrary, took the line of simplification — they abandoned the inter-axle differential at all, replacing it with a visco-coupler. The 1985 Volkswagen Golf II Syncro became the first European passenger car with such a transmission – its transmission was developed by engineers from GKN, which acquired FFD back in 1969. Simplicity and unification of the all-wheel-drive model with the basic one were the advantages of such a scheme. Under normal conditions, the car retained characteristics and controllability of the front-wheel-drive one, and when the front wheels slipped, the visco-coupler was triggered after 0.2 seconds, capable of distributing up to 70% of the torque to the rear.

Let’s pay attention to the VW Golf III Syncro’s transmission. The transfer case is attached to the gearbox, and the visco-coupler is installed in the block with the main transmission of the rear axle and connects the drive to the rear wheels when the front wheels slip. On VW Golf IV, the Haldex coupler took the place of the visco-coupler.

But such a “simplified” drive of the rear wheels had a significant drawback — even a slight delay in the operation of the visco-coupler aggravated the ambiguity of reactions. When the gas was supplied in a slippery turn, the car first drifted outwards as a front-wheel-drive one, and then, with the connection of the rear wheels, it changed its driving behaviour dramatically — and could go into a skid.

The Japanese distinguished themselves here — they repeatedly tried to smooth out this drawback by selecting the characteristics of visco-couplers and using them not only to turn on the drive on rear wheels, but also to block inter-wheel differentials. There were as many as three visco-couplers on some models (for example, the 1988 Nissan Sunny/Pulsar): one included a rear wheel drive, and the other two served to block inter-wheel differentials. In the Mazda Concerto 4WD, the visco-couplers replaced not only the inter-axle, but also the rear inter-wheel differential…

But then it turned out that it is much more convenient to use just a friction clutch, packs of which are compressed by a hydraulic drive, instead of a visco-coupler in the rear wheel drive. And electronics can perfectly control the compression of friction clutches, and hence adjust the value of torque applied to the rear wheels.

Today, most passenger four-wheel-drive cars and SUVs have a controlled clutch in the drive of one of the axles — whether it is Haldex on VW Golf platform cars, the VTM-4 system from Honda or xDrive on BMWs. Moreover, the fast operation speed of modern clutches has made the delay in connecting the wheels almost imperceptible — now everything depends only on how the control electronics are configured. For example, the transmissions of the Golf 4Motion and the Audi A3 Quattro are completely identical in design. But different software allows Volkswagen designers to choose a symmetrical distribution of torque between the axes, and Audi engineers prefer to distribute only 40% of thrust to the rear, giving their cars a more front-wheel-drive character. It’s a matter of taste…

And what schemes are preferred by drivers? Passenger road cars with a drive manually connected to the second axle are now, thank God, not produced. And as for the other three schemes…

Of course, from our point of view, the most interesting cars are heirs of the Ferguson Formula, in the transmissions of which there is a self-blocking inter-axle differential. And it doesn’t matter which ways the blocking is carried out — by a visco-coupler, as on Subarus, by the Torsen mechanical differential, as on the Audi A4-A6-A8 Quattro, the VW Phaeton, or by electronically controlled clutches (the Mitsubishi Lancer Evo). The main thing is that the automatically blocking “center” with proper configuration can significantly improve the handling of the car — make it safer and more pleasant for a sophisticated driver.

The main trend today is a variable thrust vector, when the torque is preemptively applied at the command of electronics to the wheel, which is able to implement it as efficiently as possible. At the moment, the Mitsubishi Lancer Evo X sedan has the most complex all-wheel-drive transmission in the world. Additional gear units are able to transfer the torque between rear wheels, the center is blocked by an electronically controlled clutch, and there is a conventional mechanical self-blocking device in the front. The era of all-wheel drive as we know it will end with the appearance of an electric car with four motor wheels.

But we also don’t discount cars with part-time rear-wheel drive – there are more and more of them. The Haldex coupling has recently been actively used by Volvo and Saab. Transmissions with open inter-axle differentials also find their application — on such high-speed cars as the Mercedes 4Matic of all classes. But on these cars, along with the differential all-wheel drive, the full-time anti-slip electronics necessarily operate, which to some extent compensates for the lack of a self-blocking mechanism.

The Haldex multi-disk clutch is triggered by the slightest mismatch of shaft rotation speeds. The rotation of any of the face cams causes the rollers to begin to roll over the working surfaces and move back and forth, pushing pistons in ring cylinders of the pump. The pistons pump oil into the slave cylinder with a piston which compresses the disk pack. But electronics, with the help of a solenoid valve, can release pressure, thereby flexibly adjusting the value of torque supplied to wheels.

However, we have recently noticed that the real driving characteristics of cars with different four-wheel-drive transmissions are getting closer to each other – of course, when driving on public roads, and not on rally tracks. And the more advanced electronic anti-slip systems and clutch control programs of the Haldex type become, the less the steerability of cars equipped with them will differ. Obviously, this is progress.

This is a translation. You can read the original here: https://www.drive.ru/technic/4efb336400f11713001e4f54.html

Published November 04, 2021 • 26m to read