Choosing the right car paint is crucial for protecting your vehicle’s body, enhancing its appearance, and maintaining its value. The type of paint and varnish coating you select affects durability, aesthetics, and even safety. This comprehensive guide will help you understand the different types of car paints available and how to choose the best one for your needs.

Understanding Car Paint Classifications

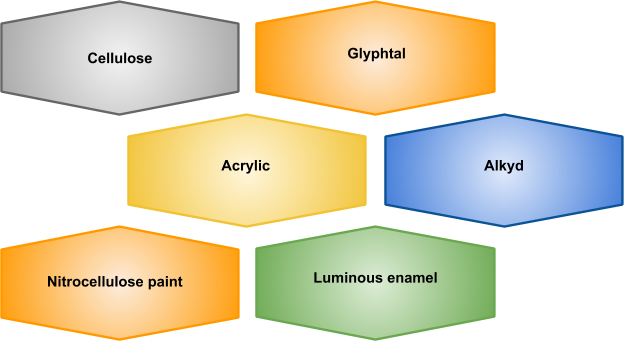

Car enamels and paints can be categorized in three main ways: by color, composition, and special effects. While color options are virtually limitless, understanding paint composition is essential for making an informed decision.

– Cellulose

– Glyphtal

– Acrylic

– Alkyd

– Nitrocellulose paint

– Luminous enamel

Cellulose Car Paint

Cellulose paint has been widely used in the automotive industry for decades. This paint type contains nitrosolvent, which evaporates quickly at normal temperatures, allowing for rapid drying.

Characteristics of Cellulose Paint

- Dries very quickly due to ultra-thin layers

- Requires multiple coats for quality results

- Each layer must be thoroughly dried before applying the next

- Loses brightness over time and requires additional polishing

- Doesn’t have natural shine when first applied

- Has a low ignition temperature, creating fire hazards

Acrylic (Polyurethane) Car Paint

Acrylic paint is one of the most popular choices for modern automotive applications, offering excellent performance at a reasonable price point.

Advantages of Acrylic Paint

- Excellent adhesive and coloring properties

- Relatively inexpensive compared to other options

- Creates durable, uniform, and glossy coating

- High resistance to mechanical damage after drying

- Excellent protection against environmental factors

- Resistant to acids, alkalis, and solvents

- Withstands solar UV radiation and precipitation

Application Process

Acrylic paint is a two-component system, with the acrylic copolymer solution (Component A) in one container and a hardener in the other. When mixed, these components trigger a polymerization process that forms a durable polyurethane acrylic film.

- Apply in two or three layers with drying between each coat

- At 20°C with normal humidity: full polymerization in 16-18 hours

- At 60°C: complete polymerization in 40-60 minutes

- Maximum hardness achieved within a few days

The finished acrylic enamel film has hardness close to glass, with excellent elasticity and durability that lasts for years.

Alkyd Car Enamel

Alkyd enamel offers the best quality-to-price ratio for automotive painting. This paint is derived from oily alkyd resin, produced through the interaction of polyatomic alcohols and polybasic acids.

Benefits of Alkyd Enamel

- Rapid polymerization at normal temperature under atmospheric oxygen

- Simple application process

- Good coverage over old coatings

- Resistance to mechanical and chemical effects

- Cost-effective solution

Drawbacks to Consider

- Long drying time due to surface film formation

- Surface film slows hardening of inner layers

- Requires additional varnish and polishing for complete car painting

To speed up drying, increase room temperature or add special accelerators. Aerosol alkyd enamel has become popular for local repairs, as the thin spray layer polymerizes and dries quickly without specialized equipment.

Glyphthal Paint

Glyphthal paints are common alkyd resins based on glycerin, phthalic anhydride, and vegetable oil. They create a thicker film on the car body surface.

Key Features

- Creates thicker protective film than standard alkyd paints

- Final coating doesn’t require polishing

- Extended drying time: 24 hours at 20-25°C

- Full resistance to solvents and mechanical impact after 15-30 days

While glyphthal paints offer advantages, the extremely long drying and curing period makes them less practical for many automotive applications.

Melamine-Alkyd Paint (Synthetic Enamel)

Also known as “hot-dried enamels,” melamine-alkyd paints are primarily used in factory settings where controlled conditions can be maintained.

Special Requirements

- Requires high-temperature drying: 110-130°C

- Best suited for specialized manufacturing facilities

- Not practical for most DIY or small shop applications

Color Options

- Rich color range available

- Multiple gloss effects: metallic, nacre, or matte

- Excellent finish quality when properly applied

Nitrocellulose Paint

Nitrocellulose enamel (NC) is designed for quick touch-ups and minor defect repairs on cars, trucks, and other vehicles.

- Extremely fast drying time

- Low resistance to atmospheric conditions

- Requires additional protective varnish coating

- Best for temporary fixes or minor repairs

Luminous Enamel

Luminous enamel contains luminophor, creating a unique glow-in-the-dark effect that makes your vehicle stand out.

How Luminous Paint Works

- Appears transparent during daytime with a glossy finish

- Absorbs sunlight throughout the day

- Emits bright glow for 6-12 hours in darkness

- Creates unique decorative effects

Advantages of Luminous Enamel

- Resistant to moisture and low temperatures

- Chemical resistance

- Protection against aggressive environmental effects

- Makes your vehicle unique and eye-catching

Methods of Applying Car Paint

There are various methods for applying automotive paint, ranging from professional equipment to convenient DIY solutions.

Professional Equipment Application

- Spray Gun: Ideal for large-volume work and complete vehicle painting

- Airbrush: Perfect for covering small areas or creating custom artwork

DIY Application Methods

Many car owners don’t have access to professional painting equipment, or the repair area is too small to justify its use. Paint manufacturers have developed convenient alternatives:

Aerosol Spray Paint

- Convenient and easy to use

- Works well on carefully prepared surfaces

- Requires proper distance to prevent drips

- Available in acrylic and alkyd formulations

- Follow manufacturer’s instructions for best results

Touch-Up Pens

- Perfect for small chips and scratches

- Can be used immediately after damage occurs

- Portable and convenient for on-the-go repairs

- Most effective for minor defects

- Limited availability for rare paint colors

- Not suitable for large damaged areas

Choosing the Right Car Paint

Selecting the appropriate car paint depends on several factors:

- Budget: Alkyd offers the best value, while acrylic provides premium performance

- Application method: DIY projects may benefit from aerosol or pen options

- Drying time requirements: Consider nitrocellulose for quick jobs or acrylic for quality

- Durability needs: Acrylic provides superior long-term protection

- Special effects: Luminous enamel for unique appearance

Understanding the different types of car paints and their applications helps you make an informed decision for your vehicle. Whether you’re doing a complete repaint, touch-up work, or creating a custom finish, choosing the right paint type ensures long-lasting protection and the appearance you desire.

Remember that regardless of which car paint you choose, maintaining proper documentation for your vehicle is essential. If you need an international driver’s license for your travels, you can process a world-class driver’s license right on our website.

Published March 29, 2019 • 6m to read