Every car disc is a guarantee of safe driving. There are a lot of advantages and disadvantages of wheel discs, and in order to orient in them, we have created this article for you. We hope that it will be useful and allow to understand the variety of light alloys from which car discs are made, as well as in the classification of the latter.

Types of discs

Car discs are divided into stamped, cast, forged and assembled. The latter are rare and exotic.

Stamped discs are the cheapest: these are the wheels that are found on basic budget cars, and they are usually covered with plastic decorative caps. These discs are made of steel and painted with enamel. Among their advantages, in addition to the lowest price, is high repairability. The fact is that stamped discs don’t break when struck, but dent (they have great impact toughness), and subsequently they can be easily repaired. The main drawback of such wheels is high weight and lack of design: this is a purely functional product. In addition, steel models are susceptible to corrosion if the integrity of the protective coating is compromised. This also includes the monotonous and bored appearance, difficulties with balancing the wheel and negative impact on the acceleration dynamics.

Cast discs are competing stamped ones in popularity. Such discs are made not of steel, but of a lighter alloy — usually aluminum. Magnesium and titanium models are much stronger and lighter than aluminum ones. Before you choose a magnesium-based alloy discs, be aware that they are less resistant to corrosion, which means you will have to constantly take care of a multi-layer protective coating. As for titanium, this is an elite group, which is completed on very expensive, sports and simply prestigious cars. Titanium models are not very cost-effective for everyday driving. Despite the strength of such products, they are prone to scratches.

Thanks to the manufacturing technology, cast discs can have the most diverse forms, which together with a weight that lower than stamped discs’ one make them popular. Among the disadvantages of such wheels, we can mention a higher price and lower repairability: cast discs don’t dent, but crack at a hard blow. Of course, the technology of welding repair and rolling has long been mastered, but it is impossible to guarantee the preservation of the original properties after repair.

Forged discs are the best quality and most expensive option. They are made by hot forging, which provides the best internal metal structure and, consequently, the highest strength with the lowest weight. The other side of this method is the low prevalence of products and high price. Forged discs are much stronger than cast ones. Instead of a porous structure, there is a multi-layered fibrous structure inside them, due to which superiority is obtained. Forged magnesium discs are the most durable and lightweight. They are also the most expensive (from thousands of dollars per disc).

In general, the average car owner chooses between inexpensive, but boring stamped discs and more expensive and nice cast ones.

Parameters taken into account when choosing discs

Of course, specialists in service centers deal themselves with all the factors and parameters they rely on in order to select the necessary discs for specific car models. If you want to navigate in them too, you should consider:

– disc type;

– mounting diameter (it is also called diameter at rim seat);

– disc width;

– PCD – pitch circle diameter;

– diameter of the center (hub) hole;

– disc offset;

– the shape of clamping holes;

– the presence of HUMP.

Remember that sometimes discs replacement changes the whole look and even style of a car.

Diameter characteristics of a disc

Diameter at rim seat means the size of the disc circumference in inches. As a rule, it is denoted by the letter R: that is, the R14 disc has a diameter of 14 inches.

It is necessary to know that the letter R doesn’t refer to the diameter itself and came from the tire parameters, where it is also mistakenly used in the meaning of “radius”, in reality implying the diameter at rim seat. In the case of the tire R, this is the marking of the radial construction of a cord, but for the disc, this marking is actually not relevant. However, the erroneous “radius” in the meaning of “diameter” and the accompanying R have become familiar, and most sellers and service centers for choosing discs already use them by default.

The permissible disc diameters for your car are indicated in the instruction manuals and on the stickers in door apertures – together with the recommended tire pressure. When buying tires, you have to remember that their diameter at rim seat should match the diameter of the discs.

You mustn’t exceed the maximum diameter specified by the manufacturer – its excess damages the suspension mount, wears the chassis. In addition, the larger the disc and the lower the tire section, the less comfort is promised by travelling on bad roads. However, changes in diameter within the limits specified in the manual, and even an inch more, as a rule, have no significant consequences.

Pitch Circle Diameter (PCD)

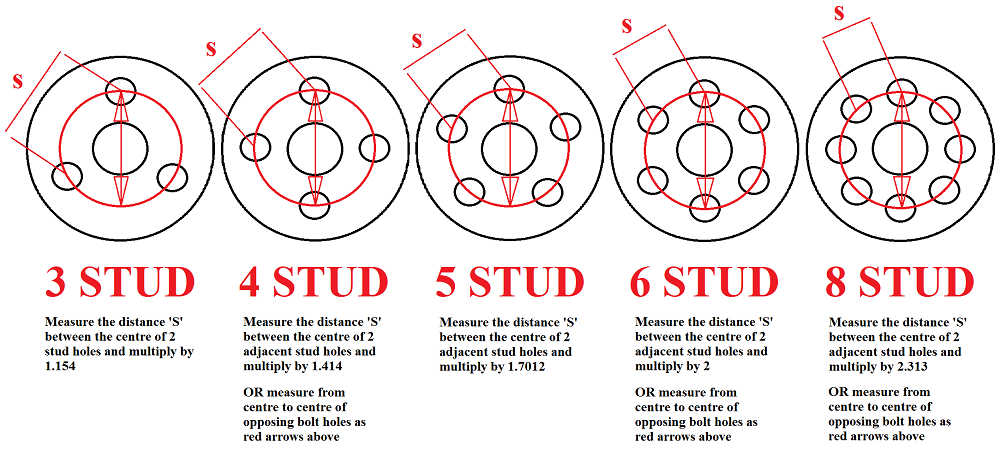

The number of holes and the diameter of the circle (location of mounting holes) is called PCD. You should avoid the use of discs with unsuitable PCD parameters.

The number of fastening bolts can be different and increases with growing mass and speed of a car: there are usually 4-6 of them, but may be more and less (at least three). Most VAZ cars have a 4×98 PCD, with the exception of the Oka (3×98) and the Niva (5×139.7), as well as new models like the Largus (4×100).

Different discs (for example, 4×100 and 4×98) look interchangeable. In fact, only two millimeters of difference lead to the fact that only one of four fasteners is correctly tightened, while the rest are displaced relative to the center, causing the wheel to beat. In part, the problem can be solved by using floating cone bolts. The latter partially compensate for the slight discrepancy between the disc’s PCD and the required parameters. The working conical part of such bolts is made as a separate ring, put on a bolt, and is displaced relative to the longitudinal axis of the bolt during tightening.

Disc width and offset

The width of a car disc in inches is denoted by the letter J in the list of parameters: for example, 5.5J is a five and a half inches wide disc.

As a rule, the width of a disc, is indicated in the same places as the permissible diameter at rim seat, along with it. In addition to the geometrical parameters for a car, the width of a disc is important when choosing tires: a tire is designed to be used with a disc of a certain width, but with a certain permissible error.

The distance between the joint face of a disc attachment to a hub and the longitudinal symmetry axis of this disc is called a disc offset. The offset is a rather important parameter: it also directly affects the operation of a suspension and hub bearings. Incorrect offset not only increases or decreases the wheel track, but can also cause accelerated wear of the chassis and bearings.

Disc offset can be positive, zero and negative: if the symmetry axis lies closer to the car than the joint face, the offset is positive, if they are on the same axis, the offset is zero, and if the symmetry axis is distant from the car more than the joint face – positive. In other words, the bigger the offset, the deeper the disc is in the wheel arch, and the smaller it is, the more the disc protrudes outside.

Diameter of a center hole

In the list of disc characteristics, the diameter of the center hole is usually denoted as “Dia”, “DIA” or “D”. This is an extremely important indicator: if the central hole of the disc is smaller than the required one, the disc simply can’t be installed, and if it is larger, balancing of the disc on the hub will certainly require centering rings.

Many people mistakenly believe that when installing a disc with a too large center hole, it will center itself on the hub by tightening the bolts, but this is not so. Accordingly, the beating and vibration, that don’t disappear after wheel balancing, is a reason to check the coincidence of diameters of the disc’s center hole and the hub and the presence of centering rings if necessary.

HUMP presence and shape of mounting holes

HUMPs are protrusions on the outer surface of the disc, that fix the tubeless tire on it. When the tire is inflated after being mounted on the disc in a tire shop, claps are heard. This is the moment of the tire fitment: the base ring sits between the hump and the disc rim. In fact, this indicator is currently almost irrelevant: almost all modern wheels are designed to install tubeless tires and have humps.

However, if you, for example, decided to purchase retro-discs of solid age, please note that they may be designed to fit only tubed tires without having hamps. However, you can install tubeless tires on them, but the question of their tight fit, as well as safety while driving, will remain open: with insufficient tire pressure, the risk of “taking shoes off” in the turn will be very great.

The shape of mounting holes is important in terms of the type of bolts or nuts that will fasten the disc. As a rule, bolts and nuts for stamped discs have only a slightly conical shape of the plane adjacent to the disc when tightening, and bolts also have a noticeably smaller length.

The latter is related to the minimum thickness of the stamped disc. The cast disc is noticeably thicker than stamped one, and in addition, its mounting hole has a more marked conical shape, which requires the use of other fasteners. In addition to the conical, the seat of the mounting hole of some discs can be designed to use fasteners with a hemispherical and flat working part.

Properly and correctly chosen car’s wheels are not only your safety and care for passengers, but also low fuel consumption along with the extended service life of the transmission and stunning view of a stylish car.

By the way, if you still don’t have an international driver’s permit, you can easily and quickly process it on our website. With an international driver’s license, you can drive a car with any discs!

Published March 01, 2019 • 8m to read