The road situation is occasionally unpredictable, and sometimes it happens that you get a flat tire quite far from the tire shop. Therefore, it is quite helpful to have such a device as a jack in your car. Today, the car market offers a huge variety of different jack models, and you need to navigate in their types and purpose of a particular modification in order not to be mistaken in a choice. In this article, we will tell you how to choose the right car jack.

Jack as a lifting mechanism

A jack is a device that distributes an applied force in such a way that the maximum lifting force is ensured with minimal effort. That is, this equipment is designed to lift heavy loads and keep them at height. Jacks can be standard, with which cars are originally equipped, and special. The main requirement for the jack is its reliability. The construction shouldn’t sag under the car weight. Reliability of a jack influences on not only safety of a car, but also safety of a person. Inspection of the suspension or replacement of the wheel shouldn’t result in injury to the driver or damage to the car.

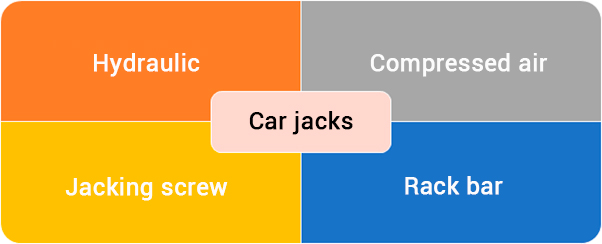

Typology of car jacks

Modern jacks are distinguished by design, principle of operation and size. There are stationary, portable, mobile, hydraulic, rack bar, compressed air jacks, as well as jacking screw. Also, every jack has its own type of drive – a way to lift the load with the help of its certain components.

The type of drive defines fluid (hydraulic jacks), air (compressed air jacks), physical effort of a person (mechanical jacks) or electric traction (electric jacks) as a “key actor”. Electric ones are ideal in operation in the auto shop or garage – but not on the road, where it’s not always possible to connect to the car electrical network. At the same time, the type of drive doesn’t play a special role, since most of jacks are either hydraulic or mechanical.

Jack hydraulics

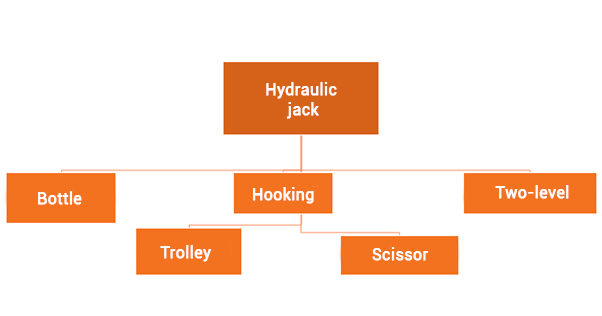

Excellent, reliable jacks, popular with motorists, are those that have a hydraulic structure. Hydraulic types of jacks work on the principle of hydraulic pump used in transport and industry. They consist of a cylinder containing liquid (usually oil), inside which a piston, valves and an injection mechanism are located. Some models use a lever mechanism and the pressure in them is injected manually. More expensive options are equipped with a small compressor powered by a car battery.

Such devices are capable of lifting huge loads, for example, two or three tons (or even five). Hydraulic jacks are also classified into different types. So, there are bottle, trolley, hooking, scissor, two-level among them. Hydraulic oil is always the working fluid there. The power pump creates a certain pressure of the working fluid, and as a result the piston moves.

Most hydraulic jacks are characterized by high efficiency, rigid construction, compactness, smooth motion and heavy-lift capacity. But they are almost all initially high, and if the car is low to the ground, they don’t fit it. In addition, the surface must be rigid and smooth. If the conditions are extreme (and drivers det a flat tire precisely in such situations), the hydraulics won’t work.

Hydraulic bottle jacks got its name from the form. The piston is located in a tank that resembles a bottle, and the injection mechanism is on the side. As a rule, such models are driven by a hand pump located near the tank. Moving the lever up and down, the driver pumps the oil from the tank to the piston, increasing its pressure. The valve doesn’t allow fluid to flow back.

Advantages of bottle jacks:

– withstand heavy loads;

– don’t require much effort to lift a car;

– low price;

– high fixity.

Disadvantages of bottle jacks:

– large mass;

– small lift height;

– low resistance to wear;

– transportation in vertical position is required.

Hydraulically operated trolley jacks are actively used in tire repair shops and car service stations. Structurally, devices of this type is a hybrid of a hydraulic and mechanical jack. The force is transmitted by an oil hydraulic pump, but the lift is carried out by means of a lever mechanism. All their parts (hydraulic plunger, pump, lever) are mounted on a low trolley with wheels.

Among the advantages of the trolley jack, there is a high lifting height, a very little effort for lifting, good load capacity, compatibility with almost any car. But there are also disadvantages: high cost, large size and mass, sensitivity to terrain and surface hardness.

Jacking screws: workers and assistants

Jacking screw is very easy to use, furthermore, quite popular among motorists. There are usually two modifications of jacking screws: rhombic and lever. The load is lifted by a screw, and the latter is controlled by a handle. Screw or rhombic jacks are a construction of two supporting platforms, four profiles connected by hinges, and a screw with a thread. Two hinges (upper and lower) are rigidly attached to the platforms, two more (side ones) have an internal thread into which a threaded rod is screwed. When the screw is rotated, the thread is tightened, effort arms approach the center, due to which the diagonal between the platforms increases and the car is lifted. Usually screw-type jacks withstand loads of up to two tons, but loading modifications can be designed for up to 15 tons. The jacking screw itself has a small mass, it has a convenient working stroke and, in addition, the height of the load’s lifting is quite impressive. Jacking screws don’t need any energy sources. These parameters are appreciated in operation, jacking screws therefore are so popular. However, car repair shops don’t use them, preferring jacks with higher efficiency. In addition, in the event of overloading, the thread can be stripped, and then problems can’t be avoided.

Rack bar (high lift) jacks

Such jacks as rack bar are designed for professional use and amateur operation. The rack bar lifting device consists of a vertically arranged rack with special holes (teeth). One end of the rack is arched, located at a right angle. There are both lever rack jacks and gear ones. The number of gears determines the size of the load that can be lifted. A three-gear jack has a lifting capacity of up to 15 tons. One-gear jack is capable of lifting up to 6 tons. Rack bar jacks are easy to operate, have a great lift height and smooth motion. Among the disadvantages: a low fixity and the need for special loops near the car wheel arches.

The rack bar jack isn’t quite convenient as a lifting mechanism for travelling – it has significant weight and impressive dimensions. But the rack jack is perfect for using in a garage.

Compressed air car jacks

If you need to lift the car in any conditions, even on a surface with a significant inclination, a device that works on compressed air is perfect. A special hollow cushion made of high quality rubber is inflated with a cylinder or compressor and lifts the car. The surface on which such a jack bears also has no difference. But the cost of such lifting mechanisms is quite high, and this is the only drawback of compressed air jacks.

When choosing a jack for your four-wheel friend, consider the carrying capacity of the vehicle and operating conditions. In addition, don’t forget to take documents for the journey. If an international driver’s license isn’t yet included in this set, we invite you to process it on our website. It won’t take you much time and effort, but this document will be useful anywhere in the world.

Published July 08, 2019 • 6m to read