At the beginning of the 20th century, when design advances were in full swing, the engine with a capacity of 10 liters could be either a single-cylinder, or, for example, a straight-eight. At that time, no one was really surprised by the 23-liter straight-six engine or the seven-cylinder radial motor from an airplane installed on a car…

However, the growth of production capacity, turnover and a fierce struggle to reduce the cost of production put everything in its proper place. The simplest single-cylinder engine became a thing of the distant past for automakers. The average cylinder capacity of a conventional car engine is now from three hundred to six hundred cubic centimeters. Performance per litre – from 35 hp/l for a normally aspirated diesel to 100 hp/l for a high-power gasoline naturally aspirated engine. This is the optimum for mass-produced engines and it is simply unprofitable to go beyond it.

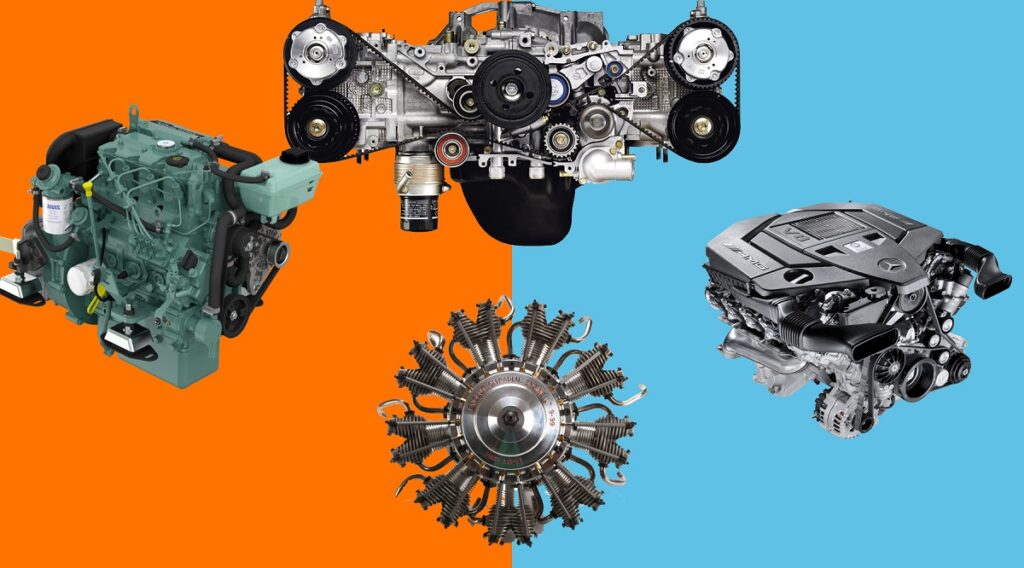

Today, the 100-hp engine has in most cases four cylinders, the 200-hp one – four, five or six cylinders, the 300-hp – eight… But how can these cylinders be arranged? In other words, according to what scheme can manufacturers build a multi-cylinder engine?

Simplicity is worse than compactness

What is the issue that is uppermost in the designer’s mind? First, the question of how to simplify the design of the engine so that it is cheaper to produce and easier to maintain. The straight engine is the simplest. To get the required capacity, designers need to arrange the required number of cylinders in a row.

Two- and three-cylinder engines aren’t often found in cars, although the trend of two-cylinder motors is gaining momentum. This is facilitated by advanced mixing systems and the use of turbocharging (as, for example, in the 85-hp two-cylinder turbo version of the Fiat 500 hatchback). But the straight-four engine fell into the most massive range of passenger cars’ capacity — from 1 to 2.4 liters.

Five-cylinder straight engines appeared on production cars relatively recently — in the mid-70s. The first was Mercedes-Benz with its diesel five-cylinder engines – they appeared in 1974 (on the 300D model with the W123 chassis). Two years later, the Audi five-cylinder two-liter gasoline engine was produced. And in the late 80s, such engines were made by Volvo and FIAT.

Straight-six engines, which until recently were so popular in Europe, have now become an endangered species in the blink of an eye. And the straight-eight engine is out of the question — manufacturers practically said goodbye to it back in the 30s. Why?

The answer is simple. The engine gets longer as the number of cylinders increases, and this creates a lot of inconvenience in the arrangement. For example, it was possible to squeeze a straight-six engine across the engine compartment of a front-wheel drive car in a few cases — only the English Austin Maxi 2200 of the mid-60s (then, the designers had to hide the gearbox under the engine) and the Volvo S80 with a super-compact gearbox come to mind.

How can a straight engine be shortened? We can “saw” it in half, put the two halves next to each other and make them work for one crankshaft. Such engines in which cylinders are arranged in the shape of the letter V are twice as short as straight ones — the most common are engines with an included angle of 60° and 90°. And a V engine with a 180° included angle, in which cylinders are arranged opposite each other, is called a flat engine (or boxer one – the designations B2, B4, B6, etc. come from this word).

Such engines are more complex than straight ones — for example, they have two cylinder heads (each with its own gasket and manifolds), more camshafts, and a more complex drive configuration. And flat engines also take up a lot of space in width. Therefore, they are used quite rarely for layout reasons — the manufacturers of boxer engines can be counted on the fingers.

And how can we make a V engine even more compact? One of the simple, at first glance, solutions is to set the included angle of the block at less than 60°. Indeed, such engines were found, but rarely – you can remember, for example, the Lancia Fulvia of the 70s with V4 engines, the included angle of its block was 23°. Why didn’t every manufacturer use it? The fact is that an engine designer always faces another problem — vibration.

Force and torque

In general, a piston internal combustion engine can’t operate without vibrations – that’s it’s design. But it is necessary to fight them, and not only to improve the comfort of passengers. Strong unbalanced vibrations can cause the destruction of motor parts — with all the consequences that fly out and fall out from it…

Why do vibrations occur? First, flashes in cylinders occur unevenly in some engine configurations. Designers avoid such schemes if possible or try to make the flywheel more massive — this helps to smooth out the torque ripples. Second, when pistons move up and down, they accelerate and then slow down, which causes the occurrence of inertial forces – akin to those that make passengers of a car bow when braking or push them into seat backs during acceleration. Third, the connecting rod in the engine doesn’t move up and down, but performs a complex movement. And the reciprocating movement of the piston from the upper dead center to the lower one can also not be described as a simple sinusoid.

Therefore, components with a doubled, tripled, or quadrupled speed of rotation of the crankshaft appear among the forces of inertia… These so-called higher-order inertial forces are usually neglected — they are very little in comparison with the main inertial force (which was assigned the first order). The exception is second-order inertial forces which have to be reckoned with. Plus, pairs of forces applied at a certain distance form torques — this happens when inertial forces in neighboring cylinders have different directions.

What can be done to balance forces and torques? First, you can choose an engine configuration in which the cylinders and crankthrows are arranged in such a way that forces and torques will mutually balance each other — they will always be equal and have opposite directions.

But what if none of the balanced schemes is suitable — for example, for layout reasons? Then, a designer can try to position crankshaft pins differently and apply all sorts of counterbalances that create forces and torques equal in magnitude, but opposite in direction to the main forces being balanced. Sometimes this can be done by placing counterbalances on the crankshaft of the engine. And sometimes – on additional shafts, which are called balance counterrotation shafts. They are called so because they rotate in a different direction than the crankshaft. But this complicates the engine and increases its cost.

There are only two types of engine among common ones that are absolutely balanced – a straight-six and a flat-six. Now you understand why BMW and Porsche hold on to such engines so tightly. And we have already mentioned the reasons why others refuse them. Now let’s take a closer look at the other configurations.

Balanced and not-so-balanced engines

Among two-cylinder engines, only one is used on cars today — a two-cylinder straight engine with a crankshaft in which the cranks have one direction (such one, for example, was installed on the Russian Oka). As you can see, this engine is similar to a single-cylinder engine in terms of balance, since both pistons move up and down simultaneously, in phase. In order to balance the free inertial forces of the first order, two shafts with counterbalances were used in the Oka engine to the left and right of the crankshaft. But what about the second-order forces? In order to cope with them, manufacturers would have to add two more balance shafts, which would be completely inappropriate on a two-cylinder engine, originally designed for small and cheap cars.

However, this is nothing — a lot of two-cylinder engines were produced without balance shafts at all. For example, such ones were installed on the little 1957 Fiat 500. Yes, there were vibrations, the manufacturer tried to dampen them with the suspension of the power unit… But the engine turned out to be simple and cheap! The cheapness of two-cylinder engines tempts developers today: it is not for nothing that this scheme was used by the creators of the most affordable car on the planet, the Indian Tata Nano hatchback.

Nowadays, a two-cylinder engine, whose cranks have different directions (at an angle of 180°), can be found only on motorcycles. It is better balanced, since the pistons in it always move in antiphase. However, a uniform alternation of flashes in cylinders can only be achieved in two-stroke engines — such engines were installed on pre-war DKWs and their direct heirs, plastic GDR Trabants. Due to the simplicity and cheapness, there were no balance shafts on them either, and drivers simply put up with the emerging vibrations.

The only car with a two-cylinder V engine is remembered – the Russian NAMI-1. And to this day, this type of engine has survived only on motorcycles — remember the American Harley Davidson and its Japanese followers with their V-two engines in all their chrome glory. Such a motor can be balanced almost completely with the help of counterbalances on the crankshaft, but it is impossible to achieve a uniform alternation of flashes. It’s a good thing that bikers don’t pay much attention to vibrations…

A three-cylinder engine is balanced worse than a straight-four one, and therefore manufacturers of three-cylinder engines, for example, Subaru and Daihatsu, try to equip them with balancer shafts. At the time, Opel engine designers decided to abandon the balancer shaft, developing a three-cylinder engine of the Ecotec family for the second-generation Corsa – in order to reduce the cost and mechanical losses. And the three-cylinder Corsa was criticized by German automotive journalists after its debut in 1996: “It is absolutely impossible to drive around the city in variable modes.”

The second-order inertial force remains free in the most popular engine among engine designers, a straight-four. It can only be balanced by a balancer shaft rotating at twice the speed. (Have you forgotten — the second-order inertial force acts with twice the frequency?) And to compensate for the torque from the balancer shaft, you will have to put another one rotating in the opposite direction. Expensive? Certainly. However, motors with balancer shafts can be found on Mitsubishi, Saab, Ford, Fiat and a variety of Volkswagen brands.

By the way, a flat-four engine is balanced better than a straight one — there is only a torque from the second-order inertial forces, which tends to turn the engine around the vertical axis. However, both the air-cooled flat engine of the legendary Beetle and the famous boxer engines of Subaru did and do without balancer shafts.

Straight-fives are not doing very well with balance. The forces of inertia are compensated, but the torque from these forces… During the operation of the engine, a wave of bending torque constantly “runs” through the block, so the block must be very rigid. However, both Mercedes-Benz, Audi, and Volvo struggle with vibrations by modifying the suspension of the power unit or using special counterbalances (like the supercharged-five 2.5 TFSI on the Audi TT RS). And only Fiat engine designers used a balancer shaft, which completely balanced all the torques.

By the way, almost all five-cylinder engines are formed by adding another cylinder to a four-cylinder engine – like bricks in a construction toy. This is done in order to get more powerful engines with minimal production and design costs. At the same time, all the stuffing, including pistons, connecting rods, valves, etc., can be taken from the four-cylinder engine. You will need a different block and cylinder head and, of course, a crankshaft, cranks of which should be arranged at an angle of 72°.

We have already mentioned six-cylinder engines, a dream in terms of balance. But in V6 engines, which displace straight-sixes, the situation with balance is the same as in the three-cylinder one, that is, not so good. Therefore, for example, the very first Mercedes-Benz V6 engine was equipped with a balancer shaft in a vee — the well-deserved M112 with three valves per cylinder. The three-liter six-cylinder engine of the PSA concern had a shaft in one of the block heads. Engineers tried not to complicate a design on other engines of that time and tried to reduce a vibration level to a minimum due to the improved suspension of the power unit and the ingenious offset arrangement of crank pins (as, for example, on the Audi V6).

Let’s add one more remark here — in V6 engines with a 90° included angle, a uniform alternation of flashes in cylinders is not provided. The resulting nonuniformity of the stroke can be compensated by a weighted flywheel, but only partially. Here is another source of vibrations for you…

V8 engines with a 90° included angle and a crankshaft cranks of which are located in two mutually perpendicular planes are very well balanced. It is possible to ensure a uniform alternation of flashes in such a motor, which also works for smooth running. Two torques remain unbalanced, which can be completely calmed with the help of two counterbalances on the crankshaft — on webs of end cylinders. Do you understand why Americans felt the great thing about V engines before others? They really don’t like vibrations and shaking in their cars…

Finally, we can talk about unusual schemes. First, let’s remember V4 engines. There were few of them — the European Ford model of the 60s (which was installed on the Ford Taunus, the Capri and the Saab 96) and a “miracle engine” of Zaporozhets. A balancing shaft was involved here for the torque from the inertial forces of the first order. However, the designers of the above-mentioned cars chose this scheme based on compactness and partly cost savings, and not for good balance.

And what about V-ten engines? The degree of balance of such motors is exactly the same as that of R5 motors. However, the designers of the former Formula 1 engines or the Dodge Viper and Dodge RAM monsters, where V10 engines are installed, didn’t think primarily about vibrations.

Well, other schemes can easily be reduced to the previous ones. For example, the flat eight (an example of application is Porsche 917 racing cars) is two fours-cylinder engines working for one crankshaft. And V-shaped and flat twelve-cylinder engines can be reduced to two straight-six engines.

VR6, VR5, W12

You know, we mentioned V-shaped motors with a small included angle of the block — as on Lancias. Before, such schemes were avoided — it is more difficult to balance them than motors with an included angle of 60° or 90°, and the gain in compactness was not valued so much then…

But now the situation has changed. Firstly, hydromounts of the power unit which significantly dampen vibrations are widely used. Secondly, the space under the hood is now worth its weight in gold. After all, who could have imagined a modest hatchback with a 2.8-liter engine before? And now – here it is! It all started with the third-generation Volkswagen Golf VR6.

The famous Volkswagen VR6 engine, a “V-shaped-straight” one (this is what the VR designation says), became a further development of V-shaped engines with a small included angle of the block. The cylinders of this engine are separated by an even smaller angle than on Lancias — only by 15°. The angle is so small that such a motor is also called “offset-straight”. An ingenious solution — the 2.8 six is more compact than a conventional V6 engine, and even has one block head!

Then the VR5 engine appeared — this is the VR6 from which one cylinder was “cut off”. After that, the engine designers of the Volkswagen concern seemed to run wild.

They came up with the W12 supercompact engine, which debuted in 1998 on the W12 Roadster concept car. These are two VR6 engines installed at an angle of 72° on one crankshaft. But before that, the W8 engine, which was installed on the top model of the Passat sedan, entered production. There are also two VR6 engines, from which two cylinders are “cut off ” and which are also combined in one block on one crankshaft. Once in Wolfsburg, they also thought about an eighteen-cylinder engine — but in the end, they stopped at the W16 with four turbochargers, which accelerates the Bugatti Veyron to 431 km/h.

Why were there no such engines before? Take a look, for example, at the crankshaft of the W12 engine — a technologist will not imagine such a thing even in his worst nightmares! A computer should help the creators of new schemes. It is very difficult to do without the help of computing power in order to calculate all the options for the included angle of the block, the location of crank pins, the order of flashes in cylinders and choose the most balanced one.

Theory and practice

As you can see, designers don’t put the degree of balance at the forefront at all when choosing a power unit scheme. The main thing is to successfully fit into the engine compartment such an engine which will have the best ratio of weight, size and power. Then, engines are now increasingly being built on a modular principle. Simply put, any engine can be built on one piston group — both a three-cylinder and a W12. After Volkswagen, more and more manufacturers are switching to modular designs. The latest line of Mercedes engines is an excellent example of this.

And vibrations… First, it is necessary to distinguish between the theoretical and actual balance of the engine. If the crankshaft assembled with the flywheel is not balanced, and pistons with connecting rods are noticeably different in weight, then even the straight-six will shake. In the end, the actual balance is always much worse than the theoretical one – for reasons of deviation of the parts from the nominal dimensions and due to deformation of the units under load. So vibrations “break out” from the engine to the outside with any scheme. Therefore, automotive engineers pay such attention to the suspension of the power unit. In fact, the design and location of the engine supports are no less important factor than the degree of balance of the motor itself…

This is a translation. You can read the original here: https://www.drive.ru/technic/4efb337600f11713001e54e1.html

Published October 28, 2021 • 17m to read